CAST TECHNOLOGY

Die casting – Gravity die casting – Investment casting – Sand casting

Even today, the various methods of casting are still highly relevant. Together with our European production partners, we fabricate challenging components from metallic materials with complex geometries using the most modern equipment.

During the product development phase, we offer advice

independent of the materials and production processes

ultimately used.

We will find the optimal process for you.

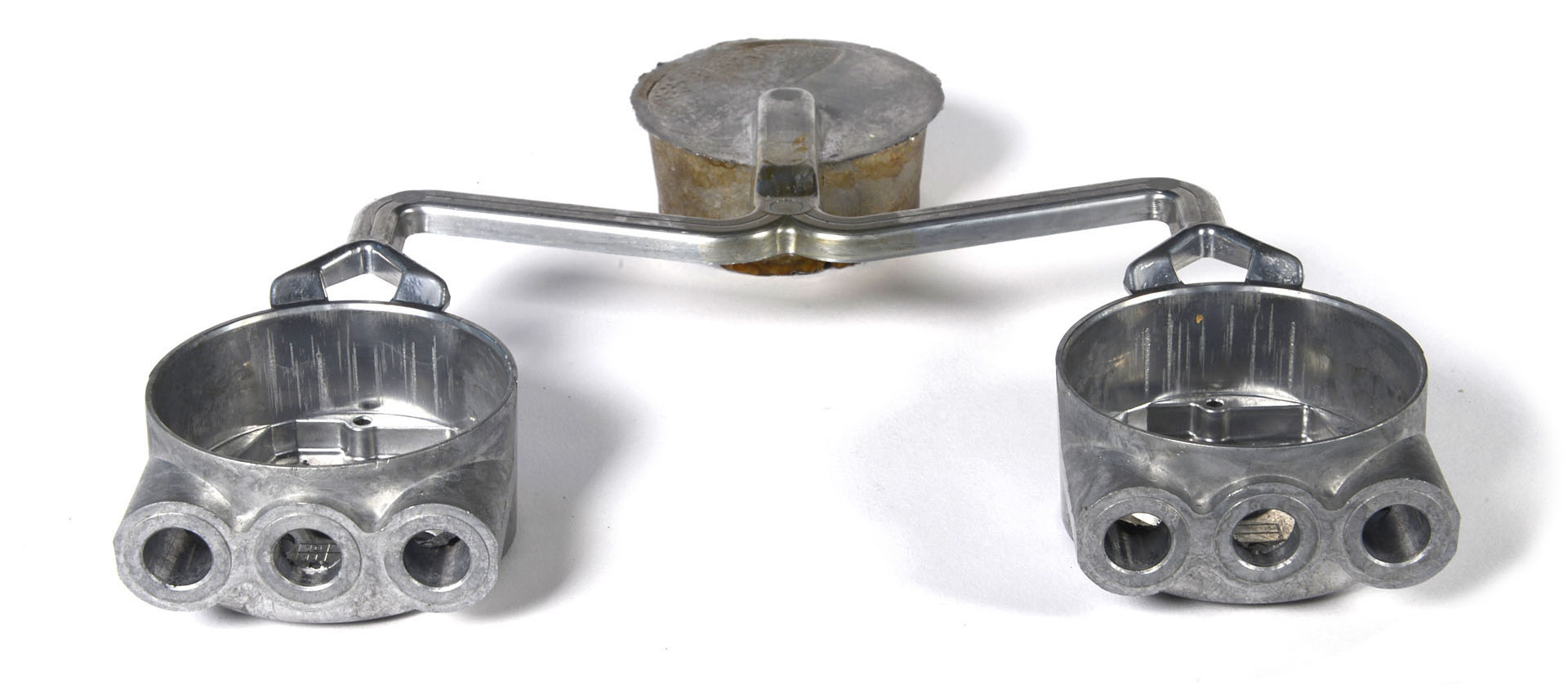

Die cast parts

with a raw weight of between 5 and 3500g are produced

from aluminium, zinc, magnesium and brass. This mould

dependant process was developed for large (many 1000s

of pieces) and very large lot sizes.

The tools (permanent moulds) are very long-lasting and

designed for many hundreds of thousands of casting

cycles.

Gravity die cast parts

are used in nearly all branches of industry due to their

excellent characteristics. Gravity die casting can even

be economical when the required number of pieces is

below 1000 casts. High dimensional accuracy, exceptional

surface finish quality and good contour reproduction are

the hallmarks of gravity die casting. As casting materials,

we process copper-zinc alloys, copper-aluminium alloys,

aluminium alloys and refined zinc alloys.

Investment casting

is a precision casting technique also known as lost-wax casting.

Investment casting oriented design often achieves

technical solutions which would be impossible, or nearly

so, by other means.

The investment casting process is characterised by nearly

unlimited freedom in shaping the parts cast, practically no

limitations on the choice of materials and a high level of

precision and surface finish quality. Investment casting is

mainly used for low per piece weights (1g to 10kg).

Sand casting

is used for the production of individual pieces, prototypes

and smaller series. The forms needed are relatively

inexpensive and can be quickly created and altered as

needed. Multi-sided forms, complicated geometries and

undercuts in technically demanding casting quality can be

realised.

English (EN)

English (EN)